Diamond Stones: What are Diamond Sharpening Stones for Sale?

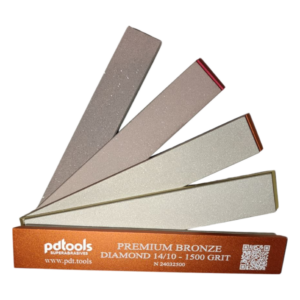

Diamond sharpening stones next to me are a tool for sharpening steel knives. They are manufactured by the world-famous Poltava Diamond Tools plant.

PDTools Superabrasives are made of synthetic diamond or cubic boron nitride of the highest grade in accordance with international quality standards and regulations.

We, USA-Market, are the official distributor. While most stones are produced by electroplating, our PDTools USA-Market sharpening stones are sintered!

This makes it possible to create a working layer of binding and abrasive, which is 30 times superior to galvanized sharpening stones, which ensures high-quality sharpening with diamond plates. They are used for working with various types of steel.

They are made of superabrasive materials and have different grit sizes. This allows you to choose the best option from the USA-Market catalog for your knife.

These bars from PDTools Superabrasives are considered a premium product and are able to provide long-lasting sharpness to your steel knife.

Features of the Diamond Sharpening Stone

So, why should you buy these bars? Diamond sharpening stones are an innovation in the world of knife sharpening.

Thanks to diamond sputtering, the hardest material available, this honing stone from USA-Market has the following features:

- Unrivaled hardness: Diamond stones can handle any steel, till 62 HRC.

- Fast and easy sharpening of steel: Superabrasives save your time.

- Durability: USA-Market honing diamond blocks last for years.

- Versatility: Diamond stones are suitable for all steel and metal knives.

Technical Characteristics of the Diamond Knife Sharpening stone

When choosing diamond sharpening stones, it is important to pay attention to their technical characteristics.

The diamond sputtering of the honing blocks affects their effectiveness in sharpening steel.

A diamond honing plate must be of high quality to ensure the sharpness of knives. The material from which the plates are made is also important – they must be resistant to wear.

USA-Market offers a premium product with honing diamond stones that meet the highest quality standards and provide excellent results in sharpening steel knives.

Diamond Sharpening Stone – Sizes and Shape

Diamond stones for sharpening are available in a wide range of sizes This is how PDTools Superabrasives, and we as their official distributor, provide a wide variety of diamond stones.

We offer diamond sharpening stones for sharpening systems and diamond bench stones. This way, everyone can choose the diamond abrasives that best suit their needs.

Sizes

- Compact: Convenient for traveling and home use.

- Standard: Universal, suitable for most tasks on steel.

- Large: Designed for professional sharpening and processing of large steel blades.

Shape

- Rectangular: The most common, convenient for sharpening steel blades of various geometries. Compatible with Apex Edge Pro, RUIXIN, TSPROF, Hapstone, etc.

Types of Bonding Material for Knife Sharpening Diamond Stone

USA-Market offers honing diamond plate sharpeners with three types of bonding material: resin bond, hybrid bond, and metal bond.

Each has its own characteristics and is suitable for different applications.

Resin Bond

- Softer bond: The honing diamond grains fall out more easily and provide for a quick steel removal rate.

- Suitable for: All types of knives, but works the best finishing sharpening, polishing steel blades, maintaining sharpness.

- Advantages: Speed, ease of sharpening, affordable price.

- Disadvantages: Lower wear resistance, susceptibility to clogging with steel particles.

Metal Bond

- Tough bond: The diamond grains are held firmly in place, which guarantees durability.

- Suitable for: All types of knives, but works the best rough sharpening, steel blade shaping, and deburring.

- Advantages: High wear resistance, resistance to clogging with steel particles, durability.

- Disadvantages:Low diamond grain self-renewal.

Hybrid Bond

- Balanced bond: Combines the properties of both resin and metal bonding.

- Suitable for: Universal sharpening that includes both coarse and fine sharpening.

- Advantages: Good wear resistance, moderate speed of sharpening, versatility, reduced susceptibility to clogging.

- Disadvantages: Higher cost compared to resin bonds, but more affordable than pure metal bonds.

What is the best way to buy a diamond sharpening stone from the USA-Market catalog?

For home use, a resin diamond stone from PDTools Superabrasives is preferable. For professionals, blocks with metal bonds and superabrasive are more suitable.

Whetstone with Grit

USA-Market offers premium abrasives with different grit sizes to meet the needs of each customer. Grit types of the diamond plate for sharpening:

- Extra coarse grit (60-100 grit)

- Coarse grit (160-240 grit)

- Medium grit (285-325 grit)

- Fine grit (550-650 grit)

- Very fine grit (1100-1500 grit)

- Extra fine grit (1700-4000 grit)

- Ultra fine grit (5000-15000 grit)

Each grit type of honing diamond stone provides a different level of sharpness for a steel knife. A coarse grit removes steel faster, while a fine grit allows for a smoother finish. The choice depends on the needs and type of steel knife.

Benefits of Using Diamond Knife Sharpener Stone

In doubt about buying? Let’s take a look at the main advantages of diamond grinding stones from the USA-Market catalog. First of all, diamond blocks are quite strong.

This means that they will not crack from a blow, like, say, artificial or natural stones.

Secondly, ease of use. Sharpening knives or any other cutting devices on honing diamond blocks does not involve the use of special oil. All that is needed is to moisten such a device with a little water before use.

To remove particles of settled steel from knife sharpening diamond stone, it is enough to rinse it under a stream of water and wipe it with a fiber cloth.

In addition, Poltava Diamond Superabrasives are very economical to use.

Application of Sharpening Stones Diamond

Diamond plate knife sharpeners from the USA-Market are not just knife sharpeners. Their unique properties make them indispensable for sharpening a wide range of cutting tools:

- Kitchen knives

- Manicure tools

- Medical instruments

- Other types of cutting tools

Thus, a honing diamond sharpening stone for knives is useful almost anywhere.

USA-Market’s extensive experience guarantees that our diamond stones will significantly extend the service life of even the most demanding blades.

Conclusion

Do you dream of a high-quality diamond bench sharpening stone?

So what are you waiting for? Contact USA-Market for a consultation and get the best sharpening diamond plate from USA-Market today!

We will find the best solution for your goals and budget.