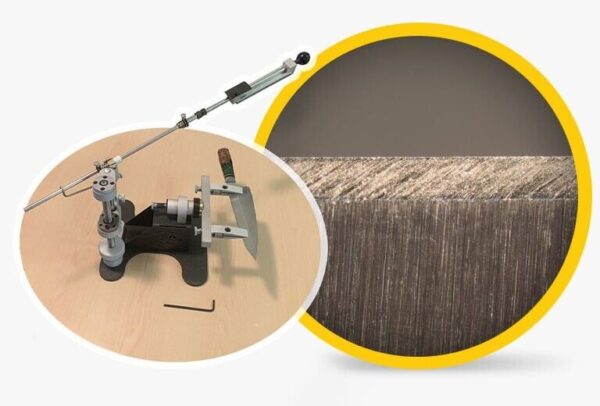

From Father of TSPROF Sharpener™, Hapstone™, Kazak™, Kadet™ etc – EFIM-2/Replica

Design features:

– Sharpening is carried out from one installation;

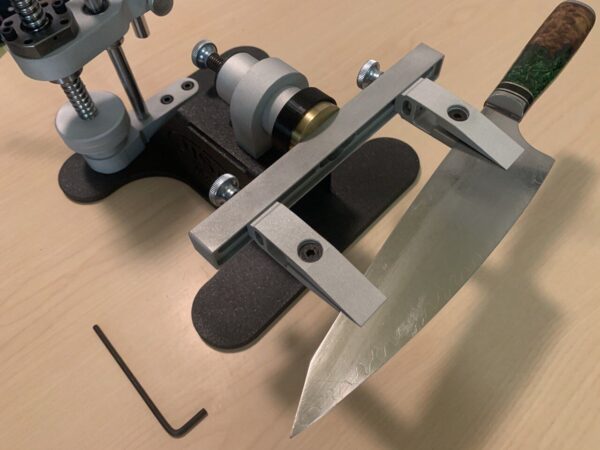

– The clamps are designed to sharpen the knives with any type of blade and their complicity;

– Clamps are interchangeable for ease of use with any size of the knife and its forms;

– Comfortable holder of abrasives allows promptly reinstall various bars and other tools;

– Retractable telescopic tool allows to adjust sharpening angle of the blade the kit also has two steps adjustments that make it more compact by height and at the same time provides smooth stroke adjustments for any angle;

– Tough monolithic design made of high-quality steel, stainless that is corrosion resistant, decorative coatings provide reliability and durability of the kit;

– Screws on clamps are made of high-quality steel.

Attention:

We do not use threads in aluminum in critical places, only a steel-to-steel bond in the production of this sharpening machine (TSPROF used to a lot of threads in aluminum in critical places!). So in the blade clamps, the quick angle adjustment unit, there are pockets for captive nuts, in case of a thread break they can be easily replaced. All screws and winglets are made of steel.

Oversized steel base made of 8 mm thick steel. allows not to fix the machine to the table with additional devices.

The swivel mechanism is made on rollers 8 * 12 mm., bushings made of “ZEDEX” polymer are installed inside, which guarantee the absence of backlash.

An additional thrust bearing is installed on the pressure lamb, which eliminates spontaneous changes in the spring pressure force.

The horizontal guide, 650 mm long, is made of a surface-hardened polished shaft with a diameter of 8 mm.

The angle adjustment mechanism is made using ball screws.

The angle range is from 5 to 31 degrees per side.

Adjustment is made steplessly with an accuracy of 0.05 degrees.

The sliding unit is made on bearings, the polymer bushing is Zedex material. The ball screw is made by grinding and has a surface hardening. Mounted on two pairs of ball bearings.

The ball screw nut is steel, it consists of a body with return channels and steel balls, anthers are located at the ends of the nut.

The additional guide is made of a 12 mm surface hardened polished shaft, a linear bearing is used for smooth running.

The screw supports and the ball screw nut holder are made of D16T alloy, thickness 20 mm.

The rotation washer is made of D16T alloy with a thickness of 20 mm. For ease of use, it has a knurling on an outer diameter of 60 mm.

This sharpening machine encluded:

Apex type abrasive holders.

Clamps size standard 2 pcs.

Parking horizontal guide.

Spring limiters of the course of a horizontal guide.

Assembly key for work

Specifications:

Sharpening angle: 11 to 30 degrees per side

Rotary mechanism: 2 positions

Materials: Steel ШХ15. Steel ST3. Brass L63T. Alloy D16T

Blade size to be sharpened: 20 to 300 mm.

Weight 8 kg.

Sharpen your sharpening skills with USA-MARKET

Reviews

There are no reviews yet.